EPERAN™ PP

Wide array of applications

Thanks to its high load characteristics, chemical resistance and strength, EPERAN™-PP expanded polypropylene foam is widely used in the automotive and HVAC industry, for technical products and for reusable or multi-trip containers. Its superior properties make it an outstanding product for impact energy absorption and weight reduction. EPERAN™-PP is also extensively used in packaging applications due to its hightemperature resistance and excellent creep characteristics, even at low densities.

Meeting the specific needs of the customer

Kaneka’s innovative EPERAN™-PP and EPERAN™ products are a direct answer to specific needs of the market in general and of its customers in particular. This has led to the development of a multitude of specialty EPERAN™-PP materials based on state-of-the-art technologies, such as dissipative types, halogen-free flame retardant grades and materials with significantly improved insulation properties, which are not only suitable for applications in the areas of construction and HVAC, but also in sectors such as public transport and aerospace.

Environmentally friendly

The environmentally friendly EPERAN™-PP and EPERAN™ foam particles allow Kaneka to easily meet the high-demanding and continuously increasing market requirements. EPERAN™-PP and EPERAN™ consist of easily recyclable polypropylene and polyethylene.

EPERAN™-PP

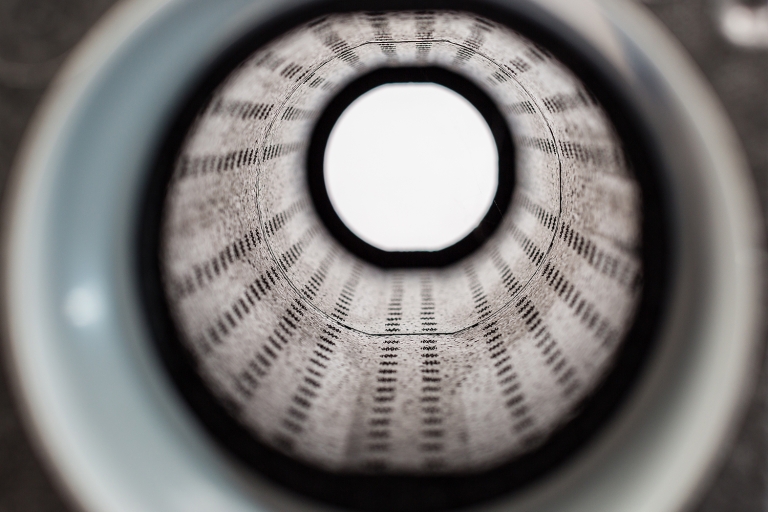

EPERAN™-PP can be easily molded into complex shapes, accommodating a multitude of possible designs, using established steam chest molding techniques. Furthermore, its outstanding mechanical properties enable EPERAN™-PP to provide ideal solutions to a multitude of applications for the automotive industry, engineering products, returnable containers, cushioning and protective packaging and many more. EPERAN™-PP is comprized of polypropylene only, making this thermoplastic material easy to recycle.

Colored EPERAN™-PP

EPERAN™-PP is available in various colors, allowing easy visual distinction or the creation of appealing products.

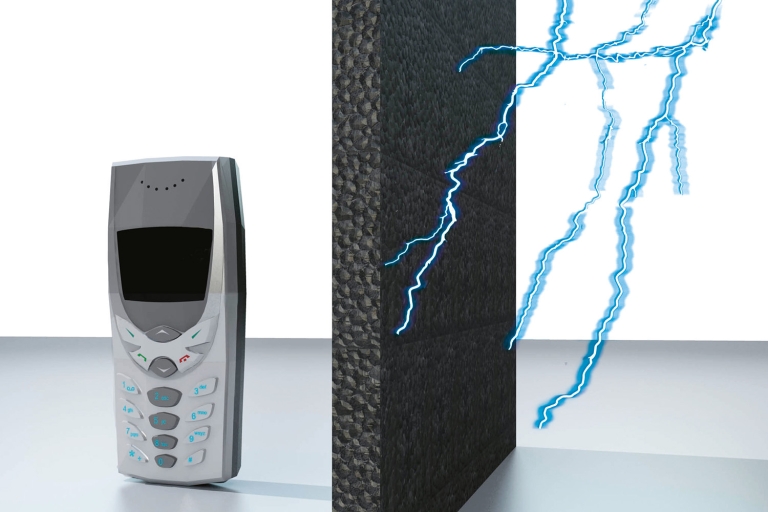

Dissipative EPERAN™-PP

Its superior electrostatic conductive properties make this material outstandingly suitable, not only for use in ESD protected areas required in the telecom, IT and other electronics businesses, but also to secure and package ESD sensitive products used in the automotive and other industries.

Halogen-free Flame Retardant EPERAN™-PP

By introducing flame retardancy in expanded polypropylene, Kaneka addressed opportunities for several applications and markets. The excellent flame retardant behavior of this 100% halogen-free material and the non-toxic smoke which it generates in case of fire allows its introduction in the field of electronic appliances, construction and HVAC and even supports applications for public transportation and aerospace.

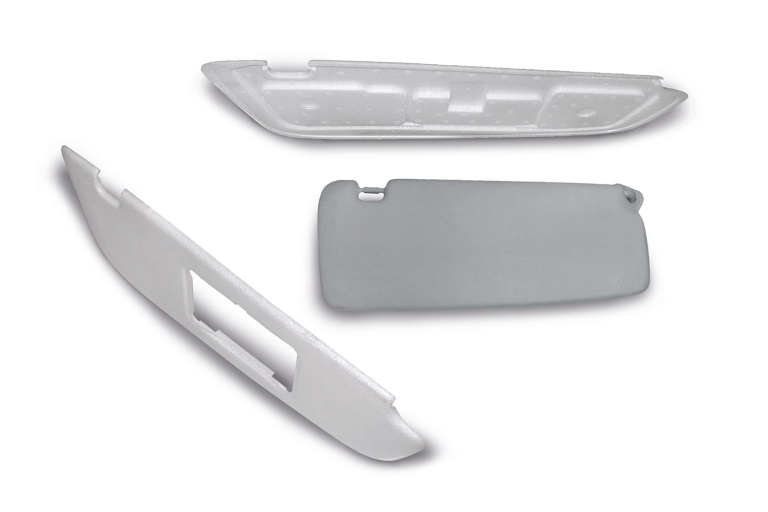

V-grade EPERAN™-PP

Kaneka was a pioneer in developing beads with a very small diameter, allowing the production of extremely thin-walled products, such as shell-type sunvisors. For any type of molding, these very small beads ensure outstandingly stable dimensional tolerances, shorter impregnation and molding cycles, easy filling and better fusion.