Structure and range

The cured material of KANEKA XMAP™ has excellent properties as a sealant or an adhesive

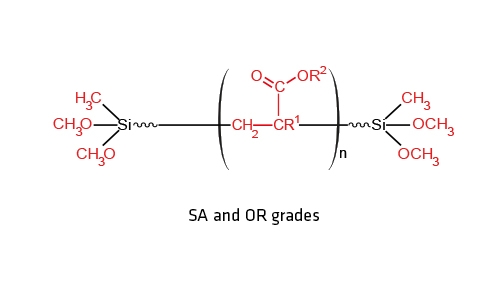

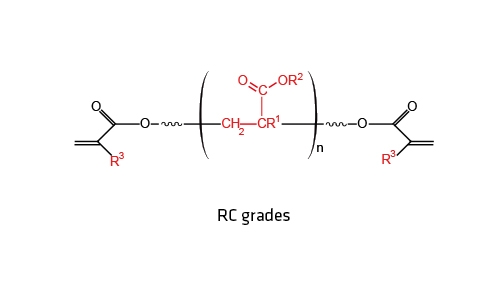

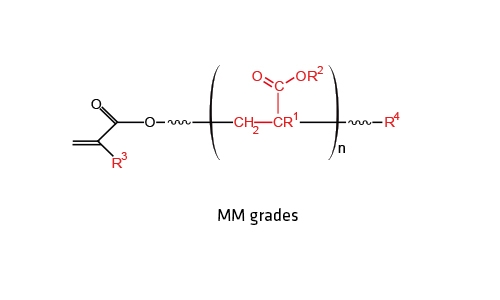

KANEKA XMAP™ is a telechelic polyacrylate that can cure through two different routes, namely condensation or radical curing process, depending on the requirements. The polyacrylate has a well-controlled structure, i.e., designed backbone, narrow polydispersity, and high functionality because of production defined by advanced living radical polymerization technology.

As a raw material base polymer, it offers the finished products excellent performance in weatherability, heat resistance, oil resistance, high gel percentage, and low compression set. The excellent performance of XMAP-based cured materials can be optimized for a variety of applications such as sealants, adhesives, coatings, gaskets, and pottings.

KANEKA XMAP™ is made by a state-of-the-art living radical polymerization technology, under which the polyacrylate polymer has a well-controlled structure, i.e., designed backbone, narrow polydispersity, and high functionality.

Features of this polymer structure:

-

low polydispersity: PDI=1.1 - 1.6 (most of grades: 1.1 - 1.3)

-

variety of molecular weight: Mn=5000 - 40000

-

high-end functionality

-

variety of main chain: homopolymers and copolymers of various acrylates

-

entire polymer backbone consists of only carbon-carbon single bond and carbon silicon bond (except end-ester group of RC and MM grades)